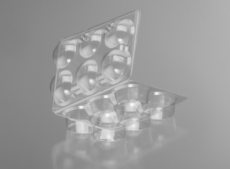

Due to our customers’ demand and the shape of the product that has to be packaged we offer packaging using very tight fitting or with bubble blister solution. In both cases in addition to the good protection these blisters can also provide a high-standard and pleasing appearance as can be seen in the pictures. There are various types of blisters and we distinguish one side blisters from two side blisters. The back side of the one side blisters are usually closed by paper or thin foil by welding them together.

Two side blisters could be made with either one or two sided tight fitting design. The two sides can be joined together by welding, using snap fit or a combined hinged/snap fit solution. These products are mainly used in the electronics, the cosmetics, the automotive as well as in the household and chemical industry. The blisters are typically made from transparent 0,2-0,5 thick films that all comply with food industry requirements and are formed by our contact or radiant heating, automatic pressureforming machines with large forming depth. Of course products with higher thickness can be made on the pertner’s demand.